An Efficiency Interlude

Whilst novel technologies and new designs are likely the future, how can we make current aircraft more efficient in the meantime?

Hello again, and welcome back to The Raven.

For the most part, I’ve focused on the potential of aircraft design to reduce aviation impact, particularly novel and innovative technology. However, bringing new aircraft to market is, as we discussed last time, a lengthy process, particularly if there are new technologies that need to be understood by regulators before certification. Even once those aircraft are out there, adoption will take a while, and there will always be markets and sectors where innovation takes much longer to trickle down.

That presents a dilemma when it comes to the climate crisis – emissions are climbing rapidly, and we collectively need to reduce them, and fast. People are not going to stop flying until new aircraft come on the market, so we need to seek reductions elsewhere. Sustainable Aviation Fuels are a possible approach (and one I may explore in a future post), but today I want to talk about operational efficiency, and highlight a company working to tackle aviation emissions in a very different but very relevant manner.

Improving Efficiency

As you might expect, a typical flight involves a host of different steps, stages and processes, and naturally some approaches to those are more efficient than others. To compare it to a more familiar scenario, when driving a car, you can put your foot flat to the floor for the whole journey, or you can drive carefully and smoothly, maintaining the engine at efficient revs, using engine braking, and so on.

When it comes to aircraft, there are a wide variety of different approaches to improve efficiency. Routing is a major factor – the most direct route may not be the most efficient, due to head-/tailwinds or other inclement weather. Some researchers have even studied the impacts of avoiding particular atmospheric conditions – many of the environmental impacts of aviation are non-CO2-based, and so avoiding particular weather can mitigate some of the effects of a flight. Surprisingly, despite potentially meaning longer or less direct routing, the overall impact might be significantly reduced.

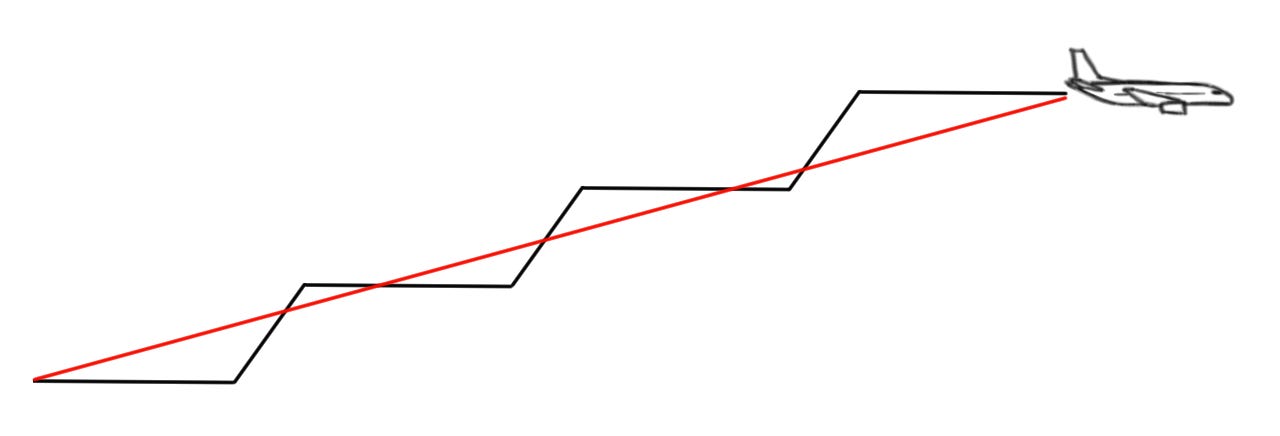

In cruise, aircraft will also often climb as they burn fuel and become lighter, to fly at maximum fuel efficiency. Safety requirements restrict aircraft to particular altitudes or flight levels, and so any climbing must be done in pre-planned steps currently, known as step climb. Advances in air traffic control could allow more aircraft to step climb, as well as allowing continuous climb in certain circumstances, realising small but significant gains in efficiency.

Similarly, picking an appropriate descent pattern can also majorly improve fuel burn. Traditional descents, which tend again to use a stepped approach, cause an aircraft to power up engines and level out multiple times as it comes in to land. An alternative approach would be, as in cruise, a continuous descent. Here, an aircraft powers back and glides in on one slope all the way through to landing. Indeed, the FAA is starting to implement this across a number of major US airports, and estimates emissions savings in the hundreds of thousands of tonnes.

There are a host of other factors large and small that can produce incremental savings as well, from engine settings to when flaps and landing gear are extended and retracted. On the ground, aircraft can sometimes be taxied on a single engine, and some operators are even looking into manoeuvring aircraft all the way to and from the runway with electric tugs or electric wheel motors to avoid running engines on the ground as much as possible.

Naturally, these all must be balanced against all-important safety considerations, as well as maintenance – in aviation there’s no such thing as a free lunch, and everything is a trade-off! However, such measures can reduce emissions on the ground and in the air, as well as saving fuel and sometimes reducing maintenance costs, so there’s a real incentive for operators to change behaviours. Many aspects of flight routing are more determined by air traffic control regulations, but even these are starting to change in recent years.

Practice what you preach

However, whilst there is significant potential for improvement, and a few pilot schemes and approaches to changing behaviour, the industry is sadly still rife with inefficient practices. One that has received widespread coverage throughout the past two years of the pandemic is the phenomenon of ‘ghost flights’. To access many busy airports, airlines must purchase slots to gain them landing and take-off space. However, to prevent cash-rich airlines buying up slots and sitting on them, regulators generally specify that airlines must use a given percentage of their slots or risk them being re-auctioned to another buyer. As demand for flights plummeted early in the pandemic, airlines found themselves in a bind – run empty ‘ghost’ flights to keep their slots, haemorrhaging money and burning through huge amounts of fuel, or give up their slots, saving money in the short term but risk lacking key routes once demand returns.

In the EU at least, regulators did eventually suspend the requirements to fly slots during the pandemic, but have eased the rules back in this winter, just as the omicron variant spread across the world, tanking demand once again.

Tankering is another common practice, and one that has largely escaped notice. Jet fuel varies significantly in price from country to country, and so airlines that cover a significant region may decide to fill their planes to the brim in locations where fuel is cheaper, saving on fuel costs at more expensive airports, effectively using their aircraft as flying tankers. This comes at a significant fuel and emissions cost – after all, the heavier an aircraft is, the more fuel it will burn. A 2019 investigation found that as many as one in five European airlines’ flights involved some tankering, and Europe-wide, the impact was equivalent to the CO2 emissions of a town of 100,000 people – all for savings as small as £10.

Encouraging efficiency

So what can be done? Clearly, we need industry practices to change, which is going to take time and pressure from airlines, manufacturers, governments and the public to shift the incentives for everyone involved. Some of the practices such as ghost flights are unlikely to change without shifts in rules and regulations, and activities like tankering are an unfortunate clash of economic and environmental considerations, and in the current climate, without significant emissions taxes, costs generally win out.

However, the tides may be changing. Major air cargo operators, both incumbents and newer entrants like Amazon, have made pledges to reach net-zero in the next couple of decades. That means alongside the existing economic forces of a low-margin business, there is now a growing pressure to monitor and reduce emissions wherever possible. Amazon for example is buying hundreds of thousands of electric vans to decarbonise its ground logistics, and investing heavily in SAFs. Of course, SAFs are far from perfect, with issues from availability and price to limited improvements in environmental benefit, but it demonstrates that firms are increasingly aware of their impact and willing to spend to reduce it.

This opens an opportunity for operators to implement more of the operational changes suggested earlier – the fuel savings rendered are not only a cost saving, but also potentially feed into those ever-more-important emissions reductions. So what does that look like?

The first step is to gather data. Many operators already gather information about both flight operations and fuel burned, but this needs to be matched up and analysed. After all, you can’t change something you don’t know about!

The second step is trickier – implementing the operational changes. Whilst planes have moved on hugely from the early days of aviation, much of the individual operational details of a flight – when flaps are raised and lowered, for example – are planned out and executed by the flight crew. Automation may eventually take over, but for the foreseeable future, pilots will be calling the shots – their judgement and expertise is still crucial to ensure safe operation.

That means any approach to improving operational efficiency is not just an operational change, but a behaviour change – tracking and pushing for improvements in pilot behaviour by suggesting changes and tweaks that produce more efficient results. This also needs to be balanced against flight performance and, of course, safety – neither should be compromised in the name of saving a few litres of Jet-A.

Introducing FuelVision

I was largely unaware of this side of aviation until early last year, when I launched this newsletter, and received an email out of the blue from one of the founders of a company looking to tackle exactly this area. We’ve chatted back and forth ever since, and I’ve been following their progress with interest.

FuelVision was founded by pilots who found themselves as of 2020 in a world where demand for flying had suddenly fallen through the floor. With their industry expertise, they realised there was a need for exactly this kind of product, helping to track and reduce emissions through small operational tweaks that could be implemented straight away.

Whilst there are already some companies working within this space, FuelVision have approached this from the pilots’ perspective. Many of the existing tools treat the pilot as a human-shaped robot operating the controls, removing their autonomy and adding yet more performance metrics to be held to. FuelVision are instead approaching this as a behaviour problem – encouraging pilots to change by explaining the how and the why – offering a way to improve their craft on their own terms. By treating pilots as human beings and individuals, they hope to improve adoption and retention over tools that reduce them to messy metrics to be optimised.

Another aspect I really like about approaches that tackle operational efficiency is that they remain relevant whatever the fuel we end up using – battery electric or hydrogen aircraft can still save fuel or energy, which will translate to better performance and cost savings, even when burning kerosene has been long left behind.

Climate is key

I realise this is a bit different from my usual fare here on The Raven, but whilst my focus remains very much on novel technologies and the design side of aviation, I want to be able to occasionally put the spotlight on other efforts to reduce the impact of aviation. Climate change is never going to be solved by a single ‘silver bullet’ solution, and the same is true for every sector and industry. We need as many approaches as possible, so if you’re working on something in this area, do reach out – I’d love to talk!

If you’ve made it all the way through, good job, and thanks for reading! Next time I hope to dive back into the weeds of conceptual design, exploring how to go from a paper napkin idea of an aircraft to a design that actually has a decent chance of working.

Oli